UR+ approved

Thinking about automating your manual vises?

Concerned about converting your manual clamping systems for automation, including new vise jaws, new programming, and new workflows?

Do you have a 4- or 5- axis CNC machine that would be difficult to route pneumatic lines to the vise?

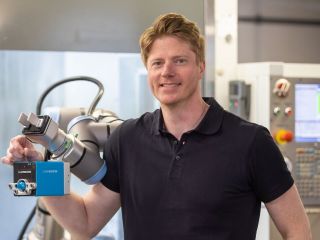

The CLAMPBOOSTER expands the cobot's/robot's capabilities by adding a drive for the CNC vises. This allows the automated clamping and unclamping of workpieces with manual vises. It´s a patented EOAT ensuring an efficient and reliable performance in high-precision clamping operations by just retrofitting existing machinery.

machinery

Choose wisely…. visely. Choose our CLAMPBOOSTER.

Interchangeable adapters make it compatible with almost all vise systems available on the market. This makes robot automation of CNC machines less complicated and less cost-intensive.

CLAMP your parts and BOOST your profits!

Your benefits with CLAMPBOOSTER:

Highest Precision

Torque and opening stroke, freely selectable in advance

With the CLAMPBOOSTER, the opening stroke of the vise can be precisely adjusted by programming the spindle revolutions. The required torque can be entered flexibly via the central control unit.

Intuitive Operation

Simple control via a display

The software-based operating process allows the CLAMPBOOSTER to be controlled via a touchscreen.

Easy Integration

No complicated or expensive investment

As an add-on component, the CLAMPBOOSTER can be used to easily upgrade existing robots. No costly machine conversions necessary.

Universal Compatibility

Compatible with nearly all vise systems available on the market

Thanks to the exchangeable adapter, the CLAMPBOOSTER is compatible with most vise systems.

Expansion of workflow

Simply expanding existing machinery

The existing, proven workflow remains unchanged and can continue as usual.

High

efficiency

Increasing production

Since the manual component is eliminated, processing can be carried out around the clock, increasing production.

CLAMPBOOSTER is proud UR+ partner

CLAMPBOOSTER is a proud UR+ partner, offering innovative solutions for automating manual clamping systems that are fully compatible with Universal Robots' collaborative robots.

CNC-Automation at its best

CNC production in a new dimension.

1.95 kg? 10 x 10 cm? Yes, it‘s the small details that define great CNC automation. And the CLAMPBOOSTER is the simple way to achieve 100% automation of your CNC production.

Take the power of your robot to a new level. Maximum efficiency and production reliability in quality and quantity thanks to highly standardized and now fully automated CNC clamping technology.

The CLAMPBOOSTER is attached directly to the robot arm. Once the robot has placed the workpiece in the vise, the CLAMPBOOSTER comes into operation: it is guided by the robot directly to the vise and tightens it according to the torque that you specified.

After processing, the CLAMPBOOSTER opens the vise. Finally, the robot unloads the workpiece and the production process can start again.

Innovation for CNC robots

Our standard for automated CNC clamping technology: Automatically moving you forward. With the CLAMPBOOSTER. Protected by patent.

Expand the possibilities of every CNC automation exponentially

Expand the possibilities of every CNC automation exponentially

The CLAMPBOOSTER expands the possibilities of every CNC robot automation. Direct installation with newly planned machining centers and uncomplicated expansion or retrofitting of existing machinery. No machine-side pre-installation is necessary.

Avoids additional investment in existing CNC machines

Avoids additional investment in existing CNC machines

CLAMPBOOSTER avoids additional investment in the outfitting of existing CNC machines. No expensive retrofitting of the machines necessary.

Alternative to complicated and costly automation

Alternative to complicated and costly automation

CLAMPBOOSTER is the alternative to complicated and costly automation of CNC machines or their vises. No conversion to automatic vise systems is required.

Greater efficiency in CNC production

Your robot can do more than load and unload. The CLAMPBOOSTER increases the efficiency of your CNC production. Proven in practice.

Promises easy integration into the workflow

Promises easy integration into the workflow

The CLAMPBOOSTER promises easy integration into the workflow through simple programming in the software-based operating method of the robot. Thanks to a self-explanatory input screen, no programming knowledge and robot know-how are required.

Can be used in all CNC production cycles

Can be used in all CNC production cycles

The CLAMPBOOSTER can be used universally in all CNC production cycles. And thanks to interchangeable adapters, it is compatible with many vise systems.

Guarantees secure clamping

Guarantees secure clamping

The CLAMPBOOSTER guarantees secure clamping of the workpiece in the clamping system, with adjustable tightening torque and high repeat accuracy in the production cycle. With unique functionality and impressive precision.

FAQs about CLAMPBOOSTER

How is the CLAMPBOOSTER operated?

Which interfaces does the CLAMPBOOSTER use to communicate with the robot?

How long does it take to set up the CLAMPBOOSTER?

Is the torque variable?

What does our after-sales service include?

Find answers to all your questions about perfection in CNC automation!

Get to know CLAMPBOOSTER yourself!

Write or call us. Experience the CLAMPBOOSTER live! Visit us for a comprehensive demonstration.

CLAMPBOOSTER is our pride and joy!

We’re idee-werk and we exemplify Industry 4.0.

We are also known for CAD construction of individual components and complex products, as well as pioneering prototypes and test samples, precision in individual parts, serial parts from CNC production, assembling components to finished complex devices.