Production in a new dimension

Robot performance at a new level

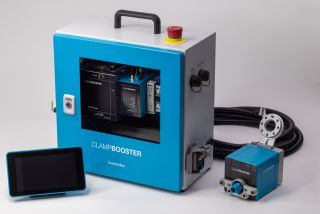

The CLAMPBOOSTER automates your CNC production and guarantees maximum efficiency and production reliability in terms of quality and quantity thanks to the perfectly standardized and now fully automated CNC clamping technology.

Technical Details for CLAMPBOOSTER

Model CB-10

Clamping and releasing workpieces in a manual vise

The game changer for the automation of CNC machines

The challenge

Simply ordering a robot and commissioning an integrator is not enough. Because: Who or what tightens the vise in a fully automated production process? And, who or what releases it again?

The answer

The CLAMPBOOSTER handles it.

The CLAMPBOOSTER extends the robot´s capabilities by adding drive for the CNC vises. This allows the robot to perform high-precision clamping operations with manual vises quickly and safely.

The existing production process remains untouched and can be continued as usual - thanks to the fully automated CNC production provided by the CLAMPBOOSTER without manual components, working 24/7.

Preparing the vise

The CLAMPBOOSTER is positioned on two dowel pins on the vise during the tightening process, eliminating torsional forces and allowing the robot to work without load. Drilling holes for these two dowel pins is the only preparation of the vise that is needed.

Attaching to the robot arm

With the cobot, the CLAMPBOOSTER is screwed between the ISO flange and the gripper. For industrial robots, mounting takes place directly on the tool flange of the robot arm.

Tightening the vise after having loaded the workpiece

Once the robot has placed the workpiece in the vise, the robot guides the CLAMPBOOSTER directly to the vise. The CLAMPBOOSTER closes the vise according to the configured torque.

Releasing the vise after machining

After the workpiece has been processed in the milling machine, the CLAMPBOOSTER opens the vise. As the final step, the robot unloads the workpiece and the production process starts again (see step 3).

By just adding one end of arm tool

The simple solution to complex automation – Automation with fewer costs upfront

Existing machines? Manual vises or clamping systems? A machine without connections for pneumatic or hydraulic lines? The CLAMPBOOSTER handles it all. Developed as an EOAT, it saves a complicated cost-intensive conversion of the machining center.

Maximum efficiency without commitment to highly complex systems.

Industrial robot or cobot? Various vise manufacturers, power-assisted systems? Using several vises on one machine? No problem for the CLAMPBOOSTER. Interchangeable adapters make it compatible with almost all systems available on the market.

Exact precision and intuitive operation.

1.95 kg? 10 x 10 cm? Yes, the torque of up to 100 Nm that the CLAMPBOOSTER can apply is enormous. It operates without load on the robot, attachment bolts in the vise eliminate torsional forces. The opening travel of the vise can be adjusted precisely by programming the spindle revolutions using a software-based operating procedure.

Yes, the torque the CLAMPBOOSTER can generate is enormous. It works without influencing the robot, pins in the vise eliminate any torsional forces.

Get in touch with us now!

We look forward to your questions.

• Fast implementation

• Increased output

• Longer machine run times

• Flexible response to a variety of requests

• Less labor-intensive production